What is Graphene: Unraveling the Marvels of a Revolutionary Material

In the realm of materials science, few substances have captured the imagination and potential for innovation quite like graphene. At its core, graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, with remarkable properties that defy conventional materials.

Material Marvel

Graphene’s allure lies in its extraordinary properties. Despite being only one atom thick, it boasts unparalleled strength, with a tensile strength approximately 200 times greater than steel. Moreover, its high electrical conductivity rivals that of copper, while its thermal conductivity exceeds that of any other known material. These attributes make graphene incredibly versatile and invaluable in various applications.

Product Pioneering

From its humble origins in the laboratory to industrial-scale production, graphene has transcended theoretical speculation to become a commercial reality. Companies worldwide are harnessing its potential to develop a diverse array of products spanning multiple sectors.

Comparing Graphene Preparation Methods: Exploring Techniques and Trade-offs

Graphene, with its exceptional properties, has sparked interest in various methods for its preparation. Let’s compare some common graphene preparation techniques:

Mechanical Exfoliation

Technique: Involves cleaving graphite using adhesive tape or mechanical shearing to obtain thin graphene layers.

Pros: Produces high-quality graphene with minimal defects and excellent electronic properties.

Cons: Labor-intensive, low scalability, and limited control over layer thickness and size.

Chemical Vapor Deposition (CVD)

Technique: Deposition of carbon atoms onto a substrate under high temperatures and controlled conditions.

Pros: Offers scalability, precise control over layer thickness, and uniformity of graphene films.

Cons: Requires specialized equipment, high cost, and typically yields polycrystalline graphene with grain boundaries and defects.

Liquid Phase Exfoliation (LPE)

Technique: Exfoliation of graphite in a solvent or surfactant to produce graphene dispersions.

Pros: Relatively simple, cost-effective, scalable, and suitable for large-scale production of graphene dispersions.

Cons: May result in graphene with variable quality, including defects and impurities depending on exfoliation conditions.

Chemical Reduction of Graphene Oxide

Technique: Reduction of graphene oxide (GO) using reducing agents to restore sp2 carbon bonds and form reduced graphene oxide (rGO).

Pros: Simple and scalable route to produce graphene-like materials from graphite oxide.

Cons: Yields graphene with reduced electrical conductivity and increased defects compared to pristine graphene.

Electrochemical Exfoliation

Technique: Electrochemical delamination of graphite electrodes in a suitable electrolyte to produce graphene.

Pros: Provides a scalable method for graphene production with control over layer thickness and size.

Cons: Requires optimization of electrolyte composition and electrochemical conditions to achieve high-quality graphene.

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

Technique: Uses plasma to enhance the growth of graphene on a substrate via chemical vapor deposition.

Pros: Enables precise control over graphene growth and doping, with potential for large-area synthesis.

Cons: Requires complex equipment and expertise, limited by substrate compatibility and growth temperature.

In conclusion, each graphene preparation method offers unique advantages and limitations. Understanding these trade-offs is essential for selecting the most suitable approach for specific applications, driving advancements in graphene-based technologies.

Types of Graphene Materials

A. Graphene Powder

Unlocking the Potential of Graphene Powder: Exploring Its Properties and Applications

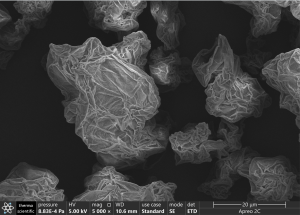

- Structure and Composition: Graphene powder consists of tiny individual graphene flakes, typically ranging in size from a few to several micrometers. These flakes are composed of a single layer of carbon atoms arranged in a hexagonal lattice structure.

- Exceptional Properties: Graphene powder exhibits extraordinary properties, including high surface area, electrical conductivity, thermal conductivity, and mechanical strength.

- Applications in Electronics and Photonics: Key component in conductive inks for flexible and transparent electrodes, graphene-based transistors, and photodetectors.

- Composite Materials and Coatings: Enhances strength, stiffness, and conductivity of polymers, metals, and ceramics.

- Energy Storage and Conversion: Revolutionizes batteries, supercapacitors, and fuel cells with high surface area and electrical conductivity.

- Environmental and Biomedical Applications: Effective adsorbent for pollutants, valuable for drug delivery, tissue engineering, and biosensing.

B. Graphene Film

Unveiling the Potential of Graphene Film: A Comprehensive Exploration

- Structure and Properties: Graphene film comprises a single layer of carbon atoms in a hexagonal pattern, offering unparalleled mechanical, electrical, and optical properties.

- Applications in Electronics: Enables ultra-thin and high-speed transistors, flexible and transparent electrodes in displays, touchscreens, and solar cells.

- Advancements in Optoelectronics: Ideal for photodetectors, photovoltaic devices, and light-emitting diodes (LEDs).

- Barrier Films and Coatings: Provides effective barrier against gases and liquids, enhancing durability and shelf life of products.

- Biomedical and Sensing Applications: Biocompatible, large surface area, and electrical conductivity make it suitable for diagnostic and therapeutic purposes.

- Environmental Impact and Sustainability: Lightweight and eco-friendly, reducing resource consumption and environmental impact.

C. Graphene Slurry

Graphene slurry, characterized by its homogeneous dispersion of graphene nanoparticles in a liquid medium, enhances various materials and processes. It is used in electronic manufacturing, energy sectors, aerospace, automotive, and construction, significantly improving performance and sustainability.

Graphene Products and Applications

- Flexible Screens: Highly malleable and transparent, ideal for smartwatches, fitness equipment, and wearable devices.

- Lithium-Ion Batteries: Efficient and reliable, offering longer life, higher energy density, and faster charging.

- Supercapacitors: Shorter charging times, longer lifespan, and higher energy density.

- Thermal Conductive Materials: Efficient heat dissipation for aviation, aerospace, electronics, and automotive industries.

- Wearable Devices: Displays and sensors for smart glasses and smartwatches, transforming daily life.

- Coating Materials: High strength and low friction, protecting and strengthening metal surfaces.

- Water Filters: Microporous structure for high-efficiency filtration, improving water purity and safety.

- Material Enhancers: Improves strength and wear resistance of metals and plastics, valuable in aerospace and automotive industries.

- Aircraft: Lightweight and high strength, ideal for aerospace vehicles.

- Energy Generation and Storage: Conductive, used in solar panels and energy storage devices for renewable energy.

Conclusion

As we delve deeper into the realm of graphene, its potential knows no bounds. From a theoretical curiosity to a driver of technological innovation, graphene exemplifies human ingenuity and scientific discovery. The graphene revolution has only just begun, and its future promises endless possibilities.